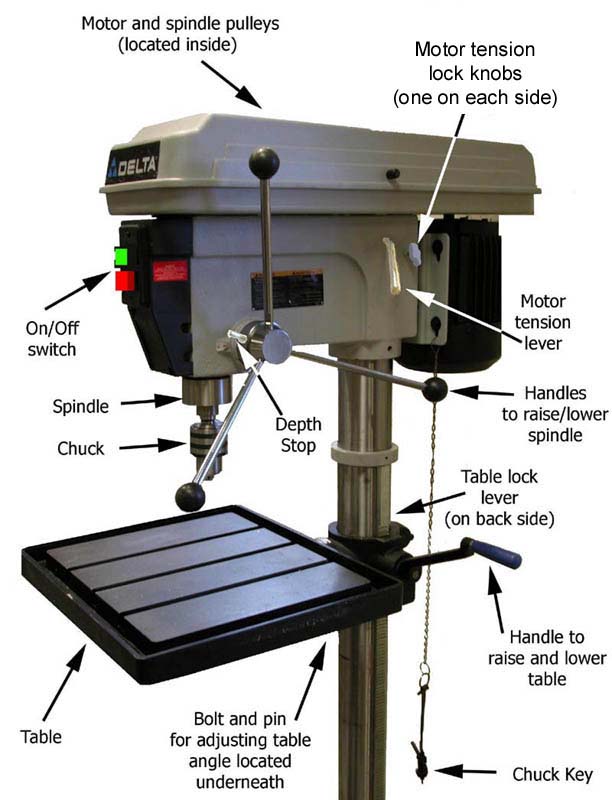

DRILL PRESS

What this tool is primarily used for:

The Drill Press is used for drilling holes in various materials. The main advantages of the Drill Press over the hand-held counterpart, the Hand Drill, are that using the Drill Press will allow you to drill with more accuracy, drill larger holes, and drill at specific angles more successfully as the Drill Press table has an inbuilt tilt mechanism. The Drill Press should come with a chart, depicting the recommended drilling speeds for various materials, and the speed setting of the machine is usually accomplished by re-positioning the motor drive belt.

A specific vice can be bought and attached to the base plate to secure work pieces.

SAFETY FOR THIS MACHINE:

ALWAYS BE AWARE of where your fingers are in relation to the drill bit

DO NOT USE bits that are dull, bent or damaged

MAKE SURE bit is centered in chuck and tightened before operating the drill

DO NOT leave chuck key in chuck while operating machine

USE A CLAMP when drilling metal, this will help prevent the material from spinning into your body or hand

NEVER hold metal in your bare hand while drilling

NEVER turn the drill press "on" before clearing the table of all objects (tools, scrap pieces, etc.)

DO NOT start the drill press with the drill bit in contact with the work piece

ALWAYS let the drill chuck come to a complete stop on its own. Never grasp the chuck in an attempt to stop the drill bit

AVOID awkward hand positions where a sudden slip could cause a hand to move into the drill bit or cutting tool

DO NOT ATTEMPT to drill material that does not have a flat surface, unless a suitable support is used

TO PREVENT ROTATION OF THE WORKPIECE, ALWAYS clamp work securely to the table or in your drill press vice

NEVER work on the drill press table while the drill is operating

THINGS TO REMEMBER WHEN USING THIS MACHINE:

Remember to re-tighten the table lock lever before using the drill

Always check the drill press speed chart to determine correct combination of material, bit size, and drilling speed

Insert drill bits about 3/4", (and at least 1/4"), into the chuck and tighten securely with the chuck key

Factors which determine the best speed:

Kind of material being worked (metal, acrylic, aluminum, wood, etc).

Size of hole

Quality of cut desired

Typically, the smaller the drill bit, the greater the required RPM

In soft materials, the speed should be higher than for hard materials

Drilling into the table not only damages the table, but also the drill bits

To prevent rotation of the work piece, clamp the work secure to the table, either with a "C" clamp or the drill press clamp

When drilling into metal, a cutting lubricant should be used. Cast iron and brass/bronze should be drilled dry

-Tbone