JIGSAW

What this tool is primarily used for:

The Jig Saw is designed for cutting curves, circles, and irregular shapes although it can also be used for straight cutting.

Sawing of metals, the basics

When sawing metal it is highly important to NOT press the saw blade hard against the material being cut. It will not make the sawing action quicker, it is more likely that you cause too much stress to the components and motor of your jigsaw. Use only a small amount of force to press the saw blade against the material being cut.

There are two other things to consider when beginning to saw metals. You should select the most appropriate blade for your metal. You should also consider using of cutting oil of some kind. This will keep the blade cooler and even sharper for longer. But when using cutting oil you will see that the metal particles like to stick to your blade, it should not do any harm but might cause extra mess.

One thing in all jigsaw blades that differ is the distance between two teeth. When selecting your blade you should know what kind of metal you're going to saw and how thick that material is. Thinner material requires a blade with smaller teeth and a smaller distance between teeth. The correct sizing of teeth prevents even the thinnest metal sheet from tearing. The general rule is that at least 3 teeth should be in contact with the metal at the same time. When this is accomplished you should not see any tearing happening.

Blades for Aluminium

Blades for aluminium usually have bigger teeth which improves the removal of chips and smaller particles. Usually when you find that it is slow to saw aluminium, its because aluminium chips can stick between the blade and the sawed material, "choking" your blade. Using cutting oil might help with this. When using cutting oil it is likely that the chips will stick to the sides of your blade. Usually blades for aluminum have so big teeth that they wont choke at all.

Blades for metal.

Blades for harder metals have more smaller teeth and are thinner. But still the same principle works: the thicker the material the bigger the teeth. But this time the hardness of the metal should be considered also. So thick and hard metal needs smaller teeth than thick but softer metals. With these kind of metals you should always use cutting oil of some kind.

For instance, a blade that has 0.7mm distance between teeth and length of an 55mm is ideal for curved cuts and layered materials, metal and PVC-plastic. I would also say that this is ideal for very thin metals (aprox. 1.4mm - 2.1mm) and even for thinner metal sheets. When using thinner (below 1.4mm) metal sheets you should also use some kind of wooden board behind and on top of the sheet to prevent it tearing and bending.

A blade that has 1.2mm between teeth and a length of 55mm will still have the same usage as the above except this blade is more efficient with thicker (and softer) metals from 2.4mm to 3.6mm. I wouldn't use this for sawing thin metal sheets since tearing is most likely to happen!

Finally a blade that has 2.0mm distance between teeth is suitable for material thickness from 4mm to 6mm.

SAFETY FOR THIS MACHINE:

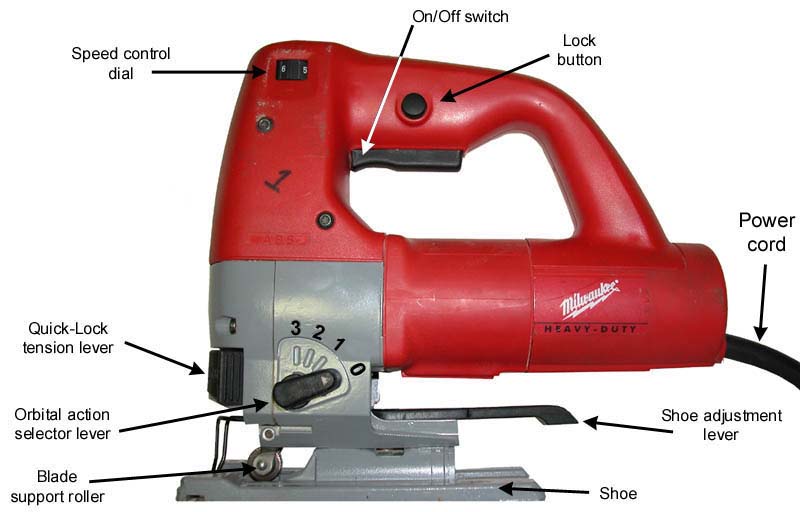

AVOID accidental starting. Be sure power switch is off before plugging in

UNPLUG tool when you need to change the blade or adjust the shoe angle

DO NOT start saw with material to be cut touching the saw blade

ALWAYS BE AWARE of where your fingers and power cord are in relation to the cutting blade

DO NOT cut metal with a blade rated for cutting wood. Typically blades for wood will have larger and fewer teeth than blades for metal (smaller and more teeth)

ALWAYS use the proper blade for the task at hand. The wrong type blade may cause the blade to seize and shake the tool violently, or may break the blade

ALWAYS USE CLAMPS when cutting any metal

BE AWARE of sharp burrs on the cut edge on metal pieces

DO NOT start cutting until the blade is moving at full speed

DO NOT FORCE the saw blade into a very tight curve too fast. You can break the saw blade

MAKE SURE blade is installed with the cutting teeth facing the front of the saw, and that it is aligned straight

DO NOT CUT without adequate clearance for the blade below the cut line. If the tip of the blade strikes down on a solid surface, it will usually break

DO NOT attempt to reinsert the blade into the cut line while the saw is running

DO NOT TOUCH the blade or reciprocating parts of the saw while it is in motion. The tip of the saw may not be visible while the saw is running

BE AWARE that the blade will be very hot after finishing a cut

THINGS TO REMEMBER WHEN USING THIS MACHINE:

Check the orbit lever before making cuts. A setting of "0" is no orbit, and a setting of "3" is maximum orbit

The orbit adjustment lever will allow you to make faster cuts, but with less precision. The cut line will be rougher

Make sure the shoe is resting flat on the material you are cutting, or the saw will be come unstable

-Tbone