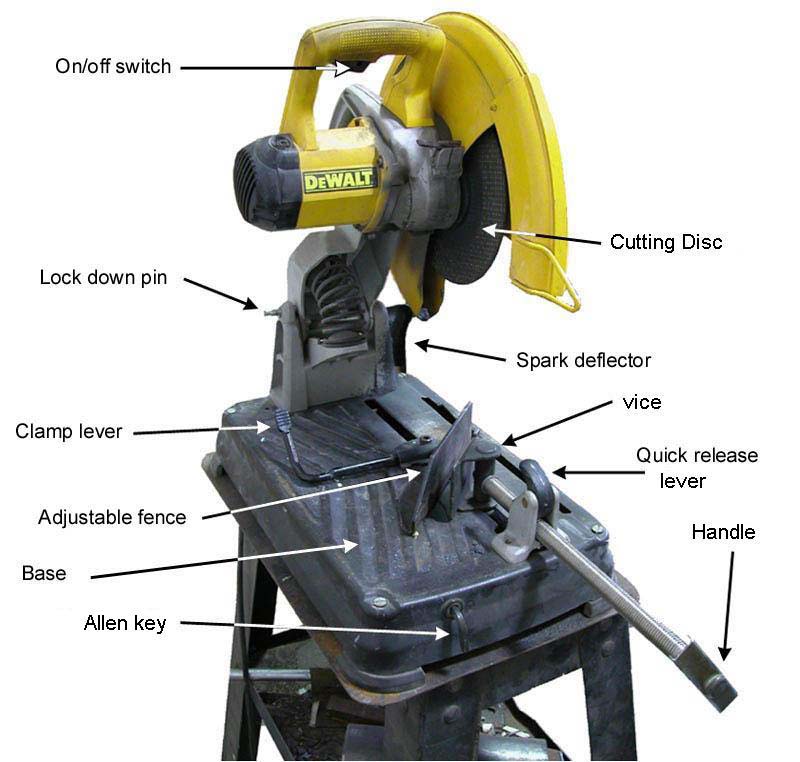

CUT-OFF SAW otherwise known as METAL CHOP SAW

What this tool is primarily used for:

The cut-off saw is used for cutting metal. It can cut pipe or flat stock perpendicular to the saw base and is only used to make straight or angled cuts. The one shown below uses an abrasive disc, (like an angle grinder), to cut through steel, although the new breed of saws use a TCT blade and can cut steel, aluminium, wood and plastics with virtually no burr or sparks using the same blade.

Operation is fairly simple. Clamp your work piece securely to the base, push in the safety button, pull the trigger and lower the now spinning disc down to make the cut. Many will have an adjustable vice allowing angles of up to 45 degrees to be cut.

Most useful for cutting the ends of pipe square, cutting plate to make brackets etc.

THINGS TO REMEMBER WHEN USING THIS MACHINE

Long work pieces must be supported by a block or material support stand so it will be level with top of base. The cutoff end should be free (not supported)

The vice has a quick travel feature. To release the vice when it is clamped tightly, turn the crank counterclockwise one or two times to remove clamping pressure

For accurate angle cutting, first use a protractor or adjustable angle to set adjustable fence

ALWAYS WEAR APPROPRIATE SAFETY CLOTHING WHEN USING THIS MACHINE

SAFETY FOR THIS MACHINE:

ALWAYS KNOW what type of metal you are cutting

DO NOT FORCE the saw to cut through material

ALWAYS USE THE VICE. NEVER attempt to hold a piece of metal and use this saw

INSPECT the cutting wheel for cracks or flaws before use. If a crack of flaw is evident, the wheel must be discarded

DO NOT CUT wood or plastic with an abrasive disc

AVOID bouncing the wheel or giving it rough treatment when in use. If this occurs during operation, stop the tool and inspect the wheel for damage

REFER to your instruction manual for further information

-Tbone